Nissan has been making significant progress in its research and development efforts, particularly in the realm of automotive materials, by harnessing the power of artificial intelligence (AI). Much like other automakers, Nissan maintains a tech lab in Silicon Valley, where engineers actively engage with cutting-edge developments in the digital world. In a recent revelation, Nissan disclosed that its Bay Area offices have been leveraging AI to expedite their research endeavors related to automotive materials, marking a pivotal shift in their approach to innovation.

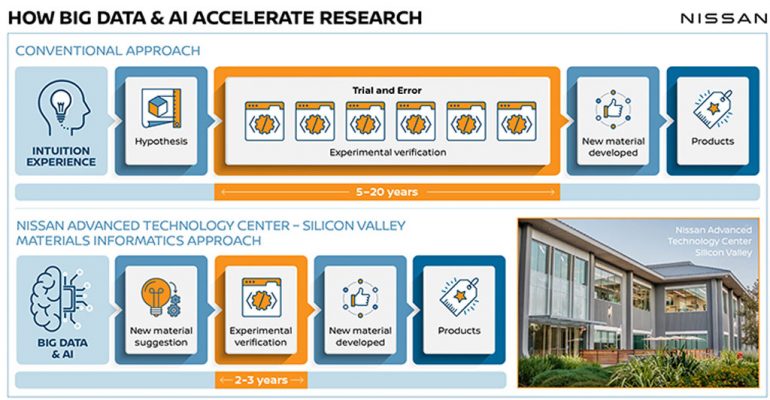

AI, while currently a buzzword with a wide array of applications, is proving to be more than just a tool for generating content or mimicking celebrities. According to Nissan, their AI-driven research and testing processes for new materials, used in various car parts, have undergone a remarkable transformation. Traditionally, this research phase took approximately two decades, replete with countless cycles of trial and error. However, with the integration of AI simulations, this laborious timeline has been dramatically truncated to a mere two years, making the process approximately 1,000 times faster.

Also, don’t forget that you can get discounted new car pricing with a free quote through qualified local dealer partners.

Bala Radhakrishnan, a principal researcher specializing in simulation at Nissan, elucidated the significance of AI in this context: “With machine learning and AI, you can simulate the properties of materials for a lot more cases than you can test experimentally, in a short time. It can help you sample millions of materials, and then screen for candidates based on the properties that you want.” Essentially, AI has empowered researchers to efficiently explore a multitude of material properties, such as strength, temperature sensitivity, and conductivity, and predict their suitability for various automotive applications.

It is imperative to differentiate Nissan’s AI from generative AI, such as ChatGPT. While generative AI generates content by drawing from existing web-based knowledge, Nissan’s AI operates within the realm of machine learning. It simulates a vast array of automotive materials and conducts rigorous tests to predict the most optimal properties for their intended use. Although AI plays a pivotal role in identifying potential candidates, human engineers remain an indispensable part of the process. They interpret the data generated by AI and conduct physical tests to validate its findings, thereby ensuring that practical applications meet the desired criteria.

One concrete example of AI’s impact is in the realm of solid-state batteries for electric cars. Nissan has set its sights on introducing these advanced batteries to the market by 2028, and AI has played a pivotal role in accelerating the development process. By swiftly identifying promising materials and properties, AI has paved the way for Nissan to make significant advancements in electric vehicle technology, bringing us closer to a future of cleaner and more efficient transportation.