General Motors has announced a strategic move towards enhancing its electric vehicle (EV) offerings by investing in a Silicon Valley startup. This investment is aimed at expediting the development of a more cost-effective battery chemistry for their future electric vehicles. The company in focus, Mitra Chem, which is situated in Mountain View, California, utilizes artificial intelligence to accelerate the advancement of lithium-ion battery materials.

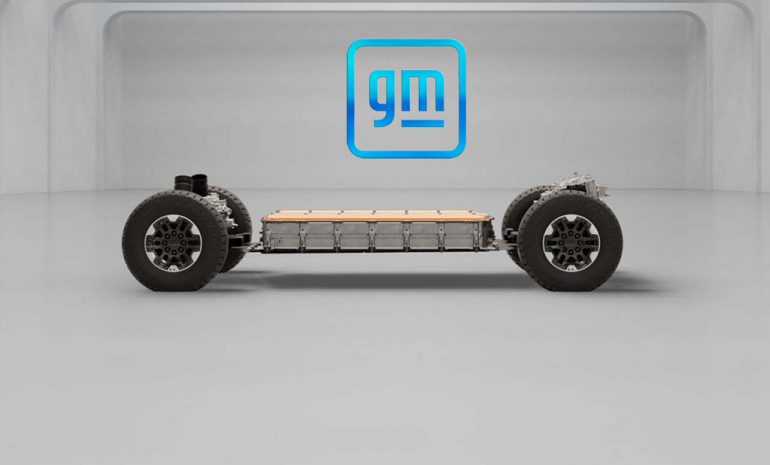

In a bid to bolster its ambitions, GM is leading a substantial $60 million investment in Mitra Chem. The startup’s specialized focus lies in the development of advanced iron-based cathode active materials, including lithium manganese iron phosphate (LMFP), which holds the potential to be integrated into GM’s upcoming Ultium batteries post-2025. These materials, namely lithium iron phosphate (LFP) and manganese-enriched LMFP, serve as more economical and eco-friendly alternatives to the current nickel-cobalt-manganese (NCM) composition commonly used in EV battery cathodes. However, it’s important to note that iron-based batteries tend to store less energy than their counterparts.

Also, don’t forget that you can get discounted new car pricing with a free quote through qualified local dealer partners.

While LFP battery cells were initially developed in the United States, the global production landscape has been dominated by Chinese companies like BYD and CATL. GM’s investment in Mitra Chem aligns with its strategic vision to establish a U.S.-based supply chain for LFP batteries and the subsequent generation of materials. This approach is reinforced by the U.S. Inflation Reduction Act, which provides incentives for sourcing battery components within North America.

Gil Golan, GM’s Vice President of Technology Acceleration and Commercialization, has underscored the significance of this investment, stating that it will not only strengthen GM’s EV battery efforts but also expedite the exploration of affordable battery chemistries such as LMFP. He pointed out that batteries crafted from iron-rich materials developed in collaboration with Mitra Chem could potentially find their way into GM vehicles in the latter half of the decade. In fact, GM is already utilizing LFP batteries in its electric vehicles in the Chinese market.

Presently, GM employs Ultium batteries that consist of cells with nickel-cobalt-manganese-aluminum cathodes. While these cathodes offer greater energy storage and extended driving ranges compared to LFP cells, they also come at a higher cost. It’s worth noting that GM’s Ultium battery plants, in partnership with LG Chem and Samsung SDI, are slated to produce cells with varying cathode compositions, including NCMA and “nickel-rich” battery cells.

The appeal of LFP and LMFP cathodes lies in their relatively greater abundance compared to materials like nickel and cobalt, which can be volatile in terms of supply and pricing. Mitra Chem, founded by Vivas Kumar, Will Chueh, and Chirranjeevi Gopal, is a driving force in this pivotal advancement toward more accessible and sustainable EV battery technologies.