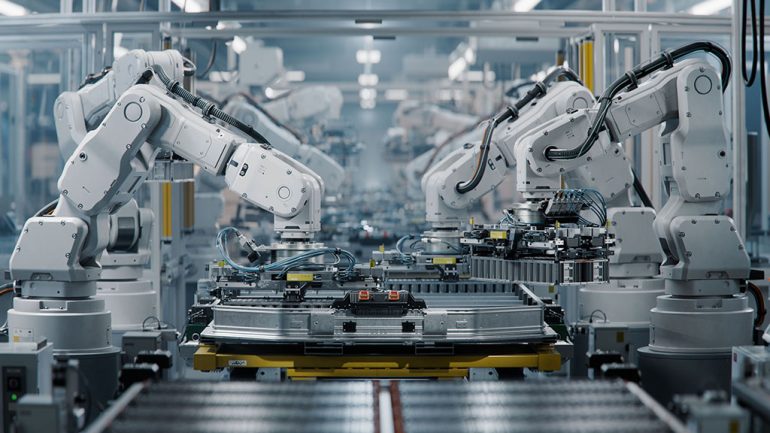

In hopes to strengthening America’s battery manufacturing sector, the U.S. Department of Energy (DOE) announced plans to award $3 billion to 25 projects across 14 states. This initiative is part of the Biden administration’s larger goal of reducing reliance on foreign supply chains, particularly from China, and accelerating the growth of electric vehicle (EV) technology.

The $3 billion investment will play a key role in enhancing domestic production of advanced batteries and critical minerals, a sector vital to the EV industry. By boosting local manufacturing, the U.S. aims to secure control over essential resources like battery-grade materials and components, aligning with the recent adoption of U.S. EV tax credit regulations that favor domestic production.

Also, don’t forget that you can get discounted new car pricing with a free quote through qualified local dealer partners.

This financial injection is expected to generate $16 billion in total investment, create 12,000 new jobs in the production and construction sectors, and secure mineral supply chains crucial for the future of clean energy. As White House climate adviser Ali Zaidi stated, “Mineral security is essential for climate security.” With these steps, the U.S. positions itself at the forefront of next-generation battery technologies, including solid-state batteries and other emerging chemistries.

Several high-profile companies and collaborative projects will benefit from these DOE awards, each contributing a critical element to the future of U.S. battery manufacturing:

The focus on recycling efforts in this project reflects the growing need to manage waste from battery production. Recycling not only reduces the environmental impact but also helps to ensure a steady supply of materials, reducing dependence on foreign suppliers.

As part of the broader battery independence strategy, DOE is also focusing on critical mineral sourcing and production. Among the notable awards:

This isn’t the first round of funding for U.S.-based battery projects. The DOE had previously allocated $1.82 billion to 14 projects, signaling the government’s consistent commitment to fostering a robust domestic battery manufacturing ecosystem. However, before the newly announced projects receive their full funding, they must complete the necessary negotiations and environmental reviews.

By investing in domestic battery production, recycling, and critical mineral sourcing, the U.S. is taking definitive steps to establish itself as a global leader in EV technology. This shift not only bolsters climate initiatives but also strengthens national security by reducing reliance on foreign suppliers for crucial battery materials.

The $3 billion investment into 25 battery manufacturing projects is more than just a financial boost. It signals a profound transformation in how the U.S. manages its supply chains and secures its place in the global EV market. By prioritizing domestic production and resource management, the country is positioning itself at the cutting edge of battery technology—a move that could reshape the future of clean energy for generations to come.

Source: Reuters